wire edm machine working principle

Mechanism for converting linear motion to unidirectional rotary motion comprising a first shaft reciprocating in a linear path pressure responsive means for moving said first shaft a second shaft journaled to rotate on its axis a third shaft journaled to rotate on its axis. Electrical Discharge Machining EDM Overview.

Mas 865 How To Make Something That Makes Almost Anything

Non-conventional material removal processes by vkjain block-4 indira gandhi national open university ignou new.

. Advanced machining processes by vk jain allied publishers new delhi. Working Principle of EDM Machining. 2D and 3D Device and Process Simulator.

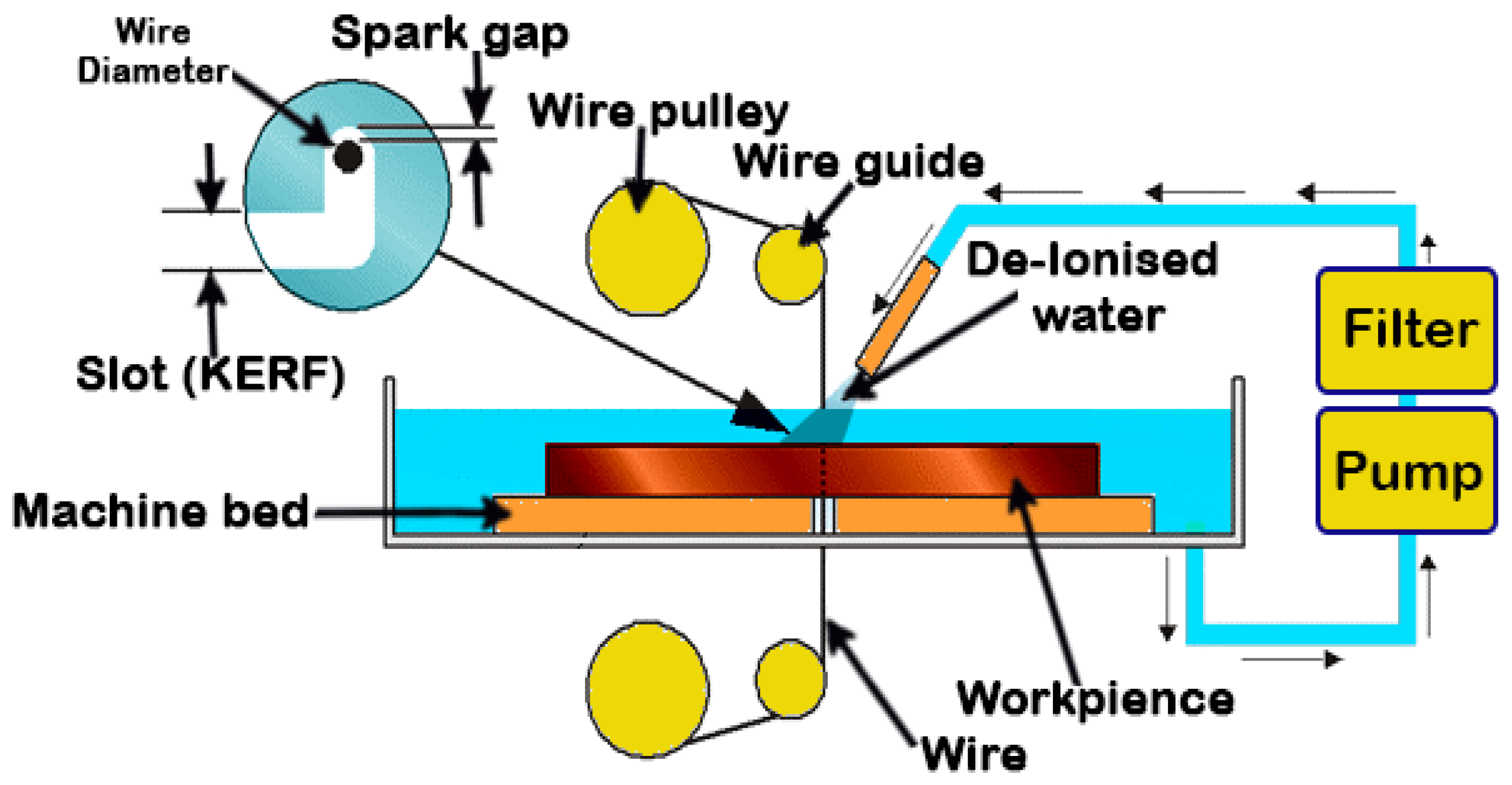

When a discharge occurs between the electrodewire and the workpiece heat energy is generated on the workpiece. Therefore laser systems are displacing conventional punching and nibbling machines from many areas of application. Introduction to micromachining vkjain editor published by narosa publishers n ew delhi 2009.

Machining and machine-tools 2013. The crank link mechanism is composed of a crankshaft a. EDM Silver Copper tool investigation.

Both camshafts were driven by a single belt which had round profile teeth for quiet operation and was constructed of wear-resistant double canvas and heat resistant rubber materials with a wire core. For the EJ251 and EJ252 engines the four valves per cylinder were actuated by shim-less type buckets ie. Wire Cut EDM Machine Wire EDM is divided into brass wire and molybdenum wire cut EDM.

The nature of the stamping process. Crank and link mechanism. He was an English physicist.

In contrast to the EDM EBM and LBM processes STEM does not leave a heat-affected layer which is liable to develop microcracks. Working principle and main components of crank press 1 Working mechanism. Electronic music is a genre of music that employs electronic musical instruments digital instruments or circuitry-based music technology in its creation.

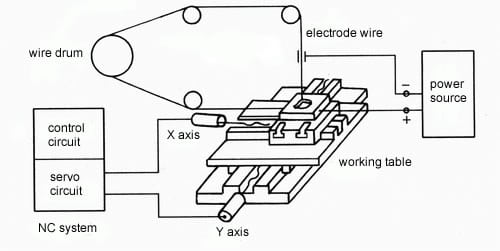

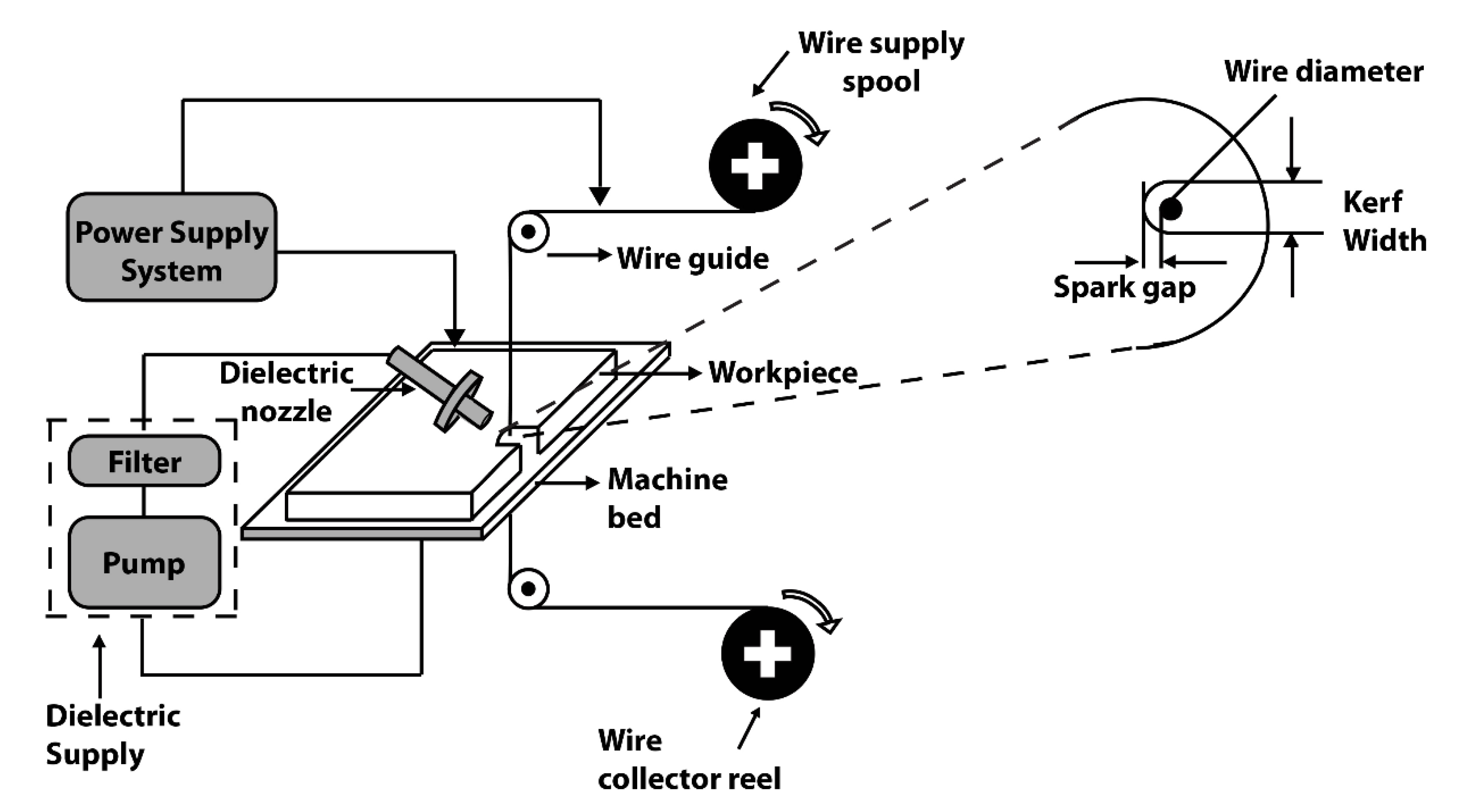

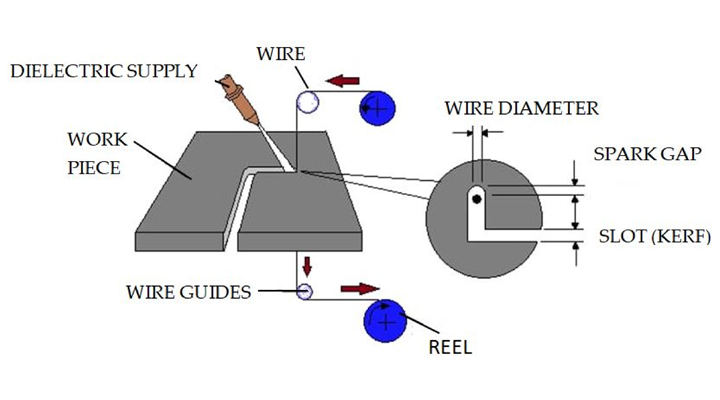

Electrical discharge machining EDM is a non-traditional machining process based on removing material from a part by means of a series of repeated electrical discharges between tools called electrodes and the part being machined in the presence of a dielectric fluid. Jain editor crc press. Additive Manufacturing is a process in which the model of an object has to be created in any Modelling SoftwareCAD Software and has to save in the format ofSTL.

It was first observed in 1770 by Joseph Priestley. In EDM machine the material is removed by rapidly recurring repeating discharges of current in between the. It includes both music made using electronic and electromechanical means electroacoustic musicPure electronic instruments depended entirely on circuitry-based sound generation for instance using devices.

EDM Electric Discharge Machining ECM Electro Chemical Machining Laser Machining. Accucell Sperm Photometer with Semen Dilutor. 2500 kN Servo Hydraulic four column loading frame and controller of Universal Testing Machine UTM MTS 31141.

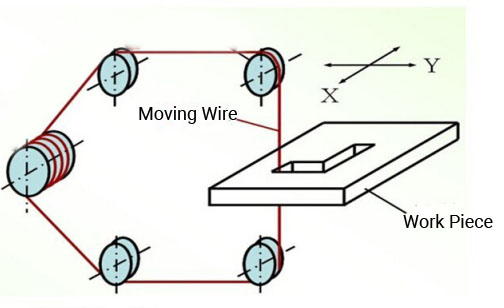

Electrical discharge machining EDM is a process of removing material by exposing it to repetitive controlled electrical discharges. Selection principle of stamping equipment. Both the tool and the workpiece must be conductors of electricity.

CNC laser cutting machines achieve the highest precision and quality in the non-contact cutting of steel stainless steel and aluminiumComplex shapes can be produced effortlessly thanks to their high laser power. Second edition micromanufacturing processes by v. In addition to the widespread CO2 laser solid-state.

Spark eroding spark machining burning wire burning die sinking or wire erosion. It is suitable for thermoelectric phenomena. A potential difference is applied in EDM machining between the tool and work material.

MTS Systems Corporation USA. One-piece solid valve lifters. Separation or molding process.

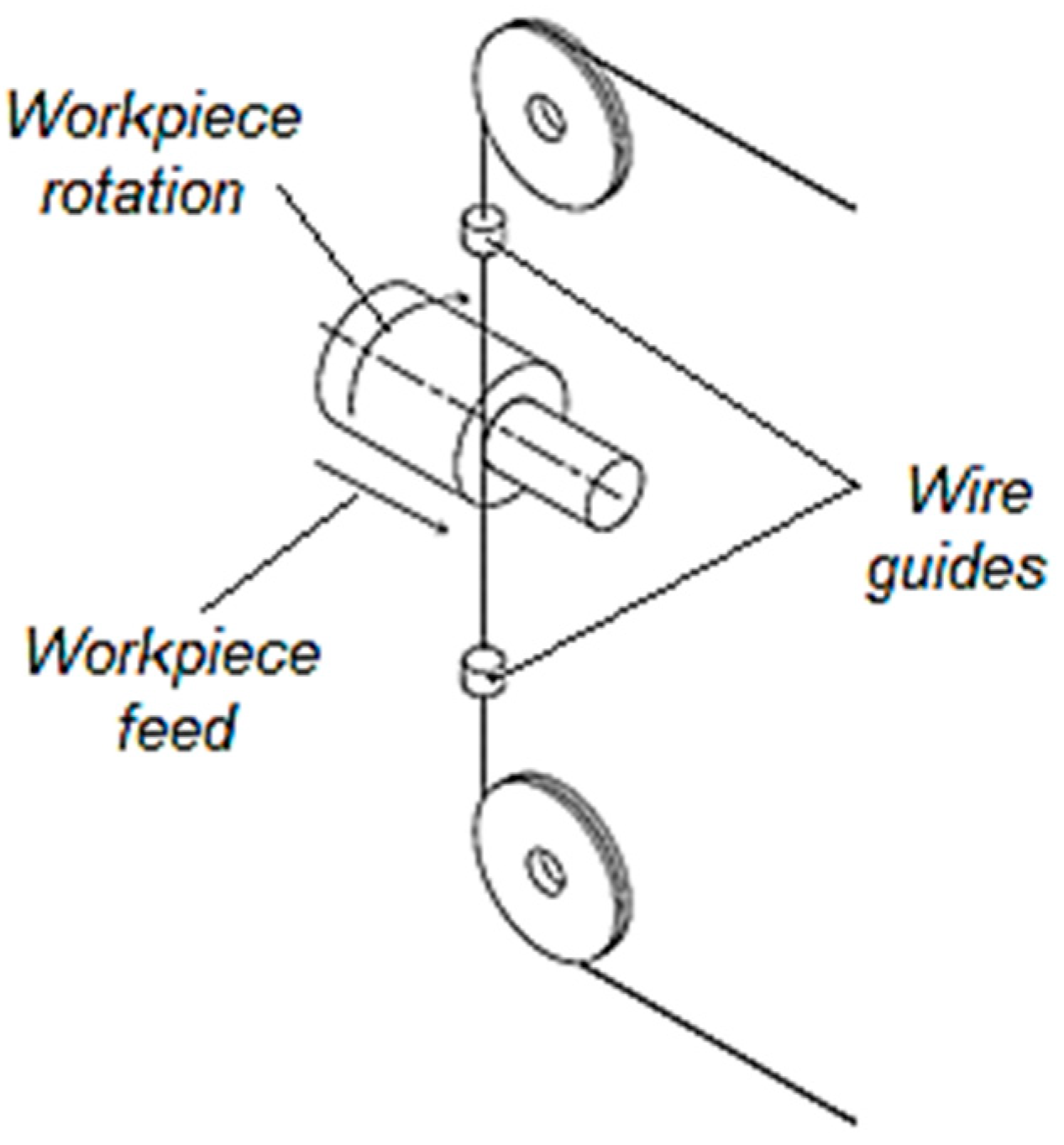

Generally electrode wires with a diameter of 01mm03mm are used to process straight-grained parts which can be punch parts or die holes. 26 Pin Flat Core Cable. Process parameters Electrolyte Type Sulfuric nitric and hydrochloric acids Concentration 1025 weight in water Temperature 38C sulfuric acid 21C others Pressure 275500 kPa Voltage Forward 814 V.

Electrical discharge machining is also known by several names which are. 3What is meant by additive manufacturing. The electrode and the workpiece move simultaneously in two horizontal directions.

Electrical Discharge Machining EDM is a non traditional machining and electro thermal process in which material from the workpiece is removed by using electrical discharges sparks.

Machines Free Full Text Wire Electrical Discharge Machining A Review Html

Wire Electrical Discharge Machining An Overview Sciencedirect Topics

What Is Edm Machining Wire Edm 101 Sans

Pdf Review Of Wire Cut Edm Process On Titanium Alloy Semantic Scholar

Wire Electrical Discharge Machining An Overview Sciencedirect Topics

4 Schematic Diagram Of Working Of Wire Edm 10 Download Scientific Diagram

Wire Electrical Discharge Machining An Overview Sciencedirect Topics

Wire Edm Guide To Edm Wirecut Machine Process Uses Fine Metalworking

Wire Electrical Discharge Machining An Overview Sciencedirect Topics

Materials Free Full Text Advanced Electric Discharge Machining Of Stainless Steels Assessment Of The State Of The Art Gaps And Future Prospect Html

How Does Wire Cutting Work Dienamics

What Is Wire Edm Electrical Discharge Machining Xact

Jmmp Free Full Text Response Surface Methodology And Artificial Neural Network Based Models For Predicting Performance Of Wire Electrical Discharge Machining Of Inconel 718 Alloy Html

Review On Wire Electrical Discharge Machining Wedm Of Aluminum Matrix Composites Semantic Scholar

Mechanical Principle 43 3q Machining Video In 2022 Steel Furniture Design Steel Furniture Mechanical Engineering Design

Sinker Edm Vs Wire Cut Edm What Is The Difference Dek

Cnc Wire Cut Cnc Wire Edm Wire Edm Wire Edm Machine Working Principle Youtube